Seawater pumps are indispensable to waterfront development projects and aquaculture facilities. Japan is a maritime nation with the sixth longest coastline in the world. Tsurumi has performed field tests in various marine construction projects under severe conditions over many years, in collaboration with general contractors, and applied the obtained know-how to developing submersible seawater-resistant pumps. Tsurumi also considers economic efficiency important and, therefore, designs pumps with “as many standardized materials as possible.”

Tsurumi’s standard pumps can be combined with a seawater-resistant kit (optional) that adds a “galvanic anode” and “seawater-resistant special cast iron impeller,” to solve both problems of long service life and cost efficiency.

Dewatering

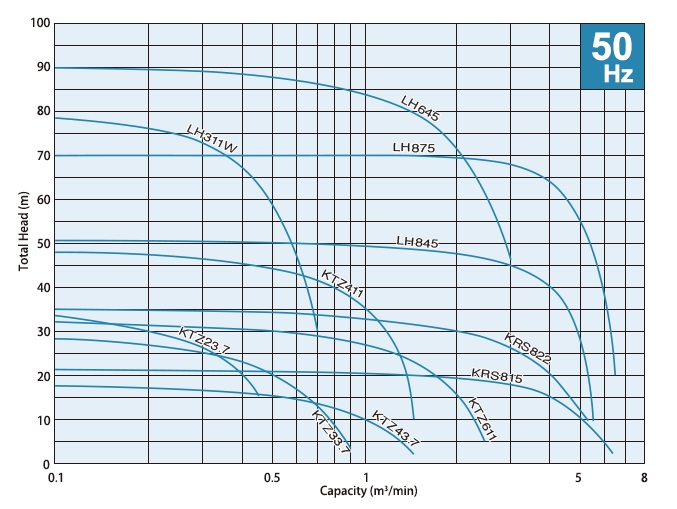

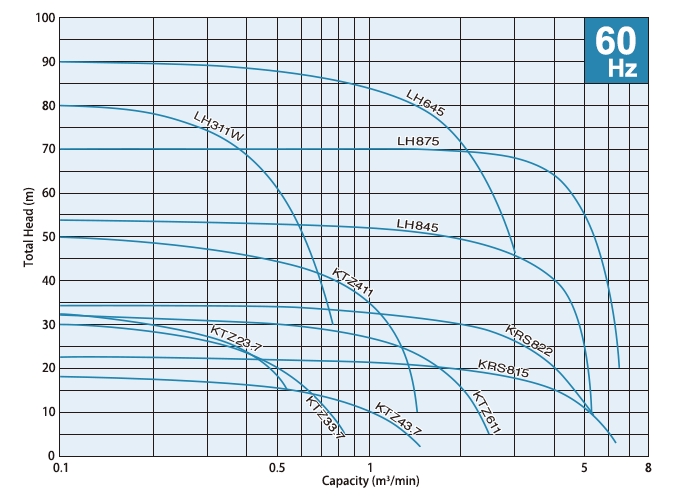

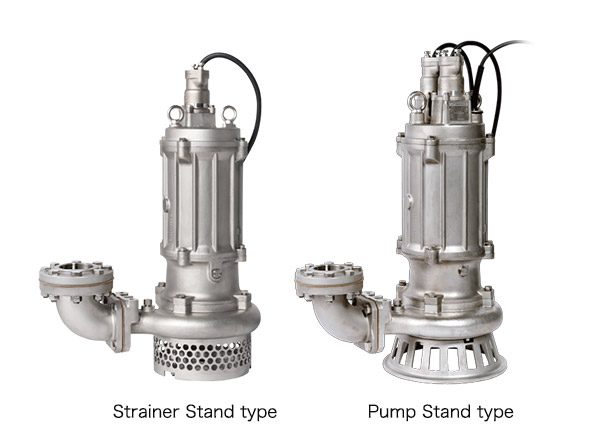

Submersible Seawater-Resistant Dewatering Pumps Lineup

Performance Curves

Sewage

Handling seawater with submersible pumps for a long term period is not an easy task. When pumps are not equipped with adequate specifications for use in seawater, corrosion in metal sections may cause the pumps to become worse in terms of performance, or in the worst case scenario, suffer a breakdown.

Supported by demonstrative experiments using seawater over a long time, Tsurumi has continued unremitting research into submersible seawater-resistant pumps, combining both corrosion resistance and durability. As a result, by giving the maximum possible consideration to economy, reliability and dependability, Tsurumi has successfully developed its original submersible seawater-resistant sewage pumps, which have achieved the upgrading of pumps to a level that allows them to withstand even the seawater.

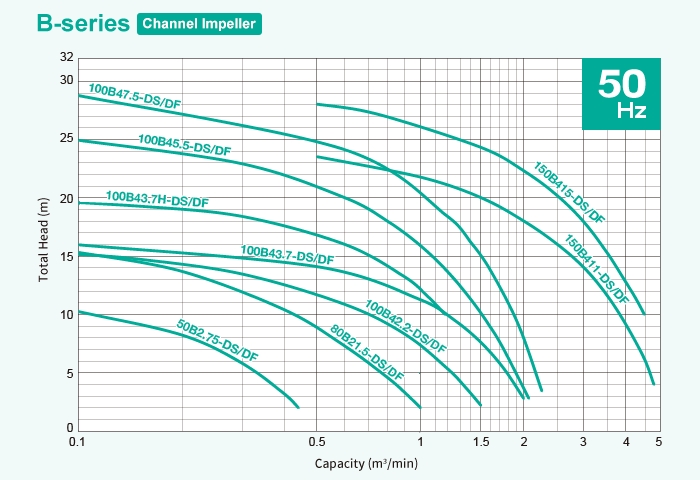

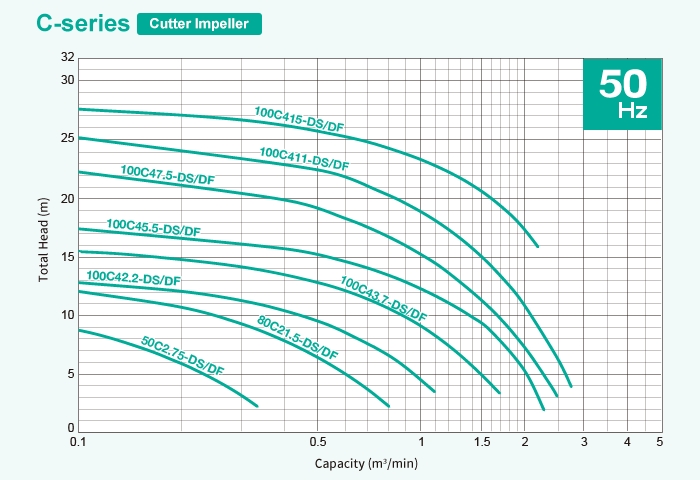

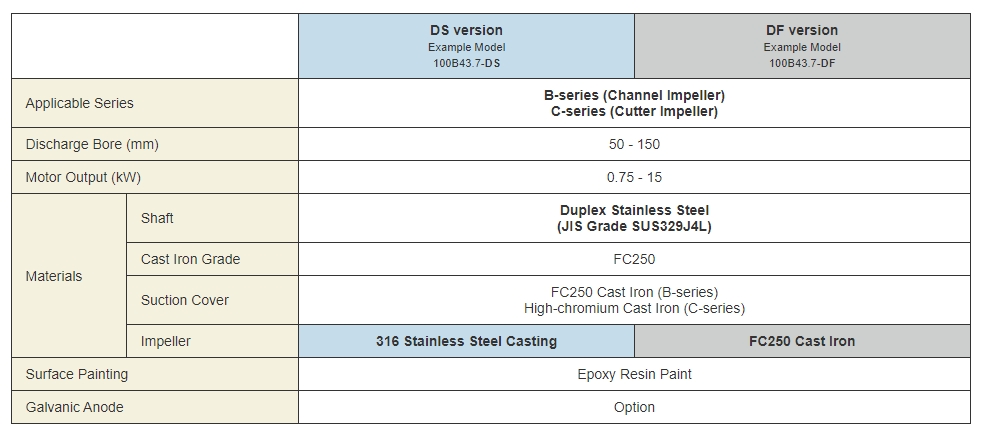

Tsurumi offers a product lineup comprising two series: B-series pumps equipped with channel impeller and C-series pumps equipped with cutter impeller, with the motor output varying from 0.75 up to 15 kW depending on the model. As part of the seawater-resistant specifications, these pumps are provided with a Duplex stainless steel shaft, a frame and a casing made of FC250 cast iron, 3-layered Epoxy resin paint coating, and a Galvanic anode (optional), with a choice of either 316 stainless steel (DS version) or FC250 (DF version) as the impeller material. In addition, these pumps are equipped with an anti-wicking cable, motor protector, dual inside mechanical seals with silicon carbide faces, Oil Lifter and the like, as in the case with standard Tsurumi products.

Submersible seawater-resistant sewage pumps have a wide range of uses including sewage drainage mixed with seawater, transfer of sewage/wastewater from water treatment facilities in plants and commercial buildings, water intake/discharge at pumping stations and shipyards in coastal areas, desalination plants and the like.

Submersible Seawater-Resistant Sewage Pumps Lineup

The B-series is a submersible channel impeller pump designed for handling raw sewage, wastewater and heavy-duty industrial applications, where the pump is subject to complete submersion and requires maximum reliability.

The C-series is a submersible cutter pump for sewage and wastewater, which is made of casting and equipped with cutting mechanism. Featuring a combination of impeller vane with brazed sintered tungsten carbide alloy edge and a suction cover of serrated shape, the C-series pumps enable smooth pumping, while cutting solid and fibrous matter during suction.

Performance Curves

For 60 Hz models, please contact us.

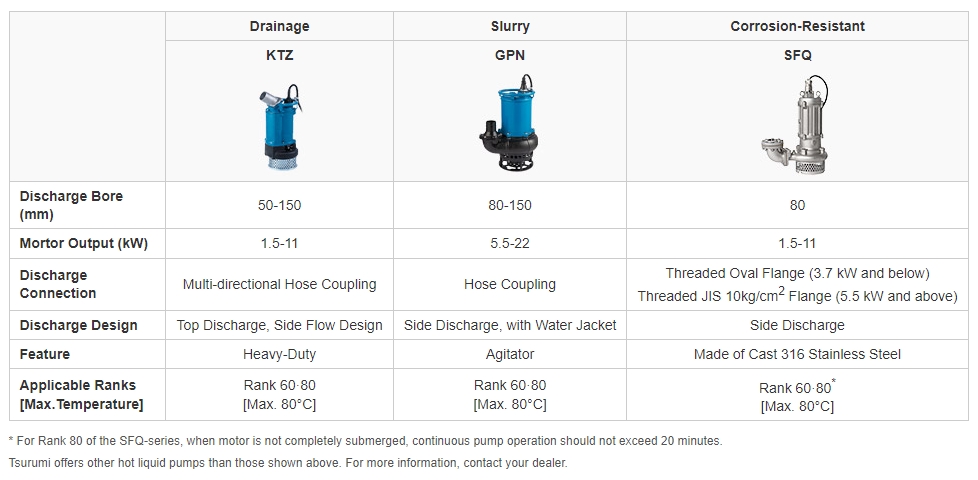

High Temperature Liquids

Tsurumi manufactures submersible pumps to handle liquids up to 80°C. Many are already in service at sites that need to discharge high temperature liquids, including industrial wastewater from power plants and steel mills, and hot spring discharge from mines in volcanic zones.

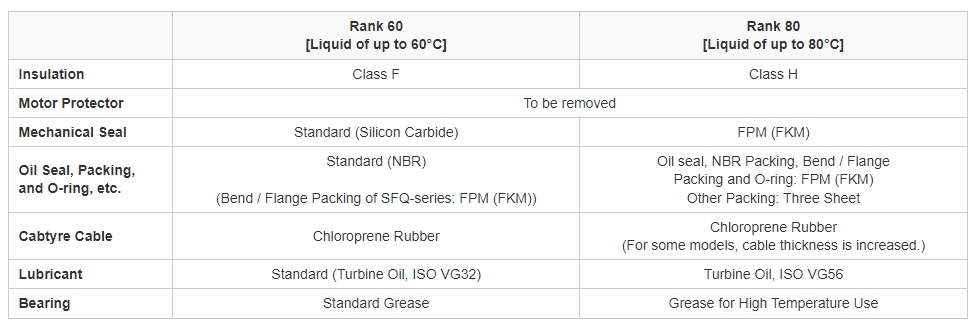

Tsurumi’s standard specification pumps can move liquids of up to 40°C, but Rank 60 and 80 pumps are available as options for liquids of 60° and 80°C, respectively. Insulation class, rubber materials, lubrication and bearing grease are upgraded for each temperature rank.

Backed by years of experience and know-how, Tsurumi develops hot liquid pumps to withstand harsh working conditions. Tsurumi also has a wide lineup of pumps for moving seawater and corrosive liquids. For more information, contact an authorized Tsurumi pump dealer.

Submersible Pumps Lineup for High Temperature Liquids

Product

Submersible Construction Dewatering Pumps

-

Portable Dewatering Pumps

-

Dewatering Pump

-

High-Head Dewatering Pumps

-

Slurry Pumps

-

Portable Residue Dewatering Pumps

-

Corrosion Resistant Pumps

-

Explosion-proof Dewatering Pumps

-

Pump for Sewage Bypass

Non-submersible Construction Dewatering Pumps

-

Engine-Driven Dewatering

-

Self-Priming Residue Dewatering Pump

Submersible Sewage & Wastewater Pumps

-

Cast Iron Pumps

-

Resin-made Pumps

Submersible Wastewater Pumps

-

Cast Iron Pumps

-

Resin-made Pumps

-

Stainless Steel Pumps

-

Cast Stainless Steel Pumps

Submersible Seawater Pumps

-

Titanium Pumps

Water Treatment Equipment

-

Multi-Disc Dehydrators

-

Multi-Disc Screw-Press Dehydrators