Vitalobe

Sturdy rotary lobe pump in hygienic design, bi-directional operation possible, horizontal or vertical orientation of connections. Hygienic design, excellent CIP/SIP compatibility due to its almost complete lack of dead volume or narrow clearances. All wetted components made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel; various rotor types, shaft seals and process connections available. Installed as a pump set with gear unit and standardised motor. Vitalobe is EHEDG-certified. The pump elastomers comply with the FDA standards and EN 1935/2004. Accessories include a trolley, a heatable casing or casing cover and a pressure relief arrangement. ATEX-compliant version available.

Main Applications

-

Food industry / beverage industry

-

Pharmaceutical industry

-

Cosmetics industry

-

General industry

-

Chemical industry

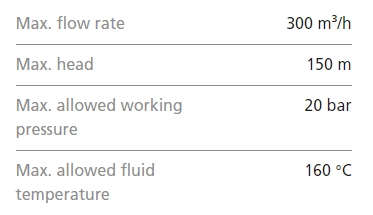

Technical Data

Benefits

-

Hygienic zero dead volume design for residue-free and fast CIP/SIP

-

Flexible with horizontal in-line or vertical in-line connections

-

Flexible with different types and materials of rotary lobes, matched to the specific application

-

Reliable with solid design of pressure-retaining and rotating parts and shafts supported on two double tapered roller bearings

-

Reliable with integrated pressure relief valve

.