INTEGRATION WHEN IT’S BEST

Less hassle. Less cost. Greater peace of mind.

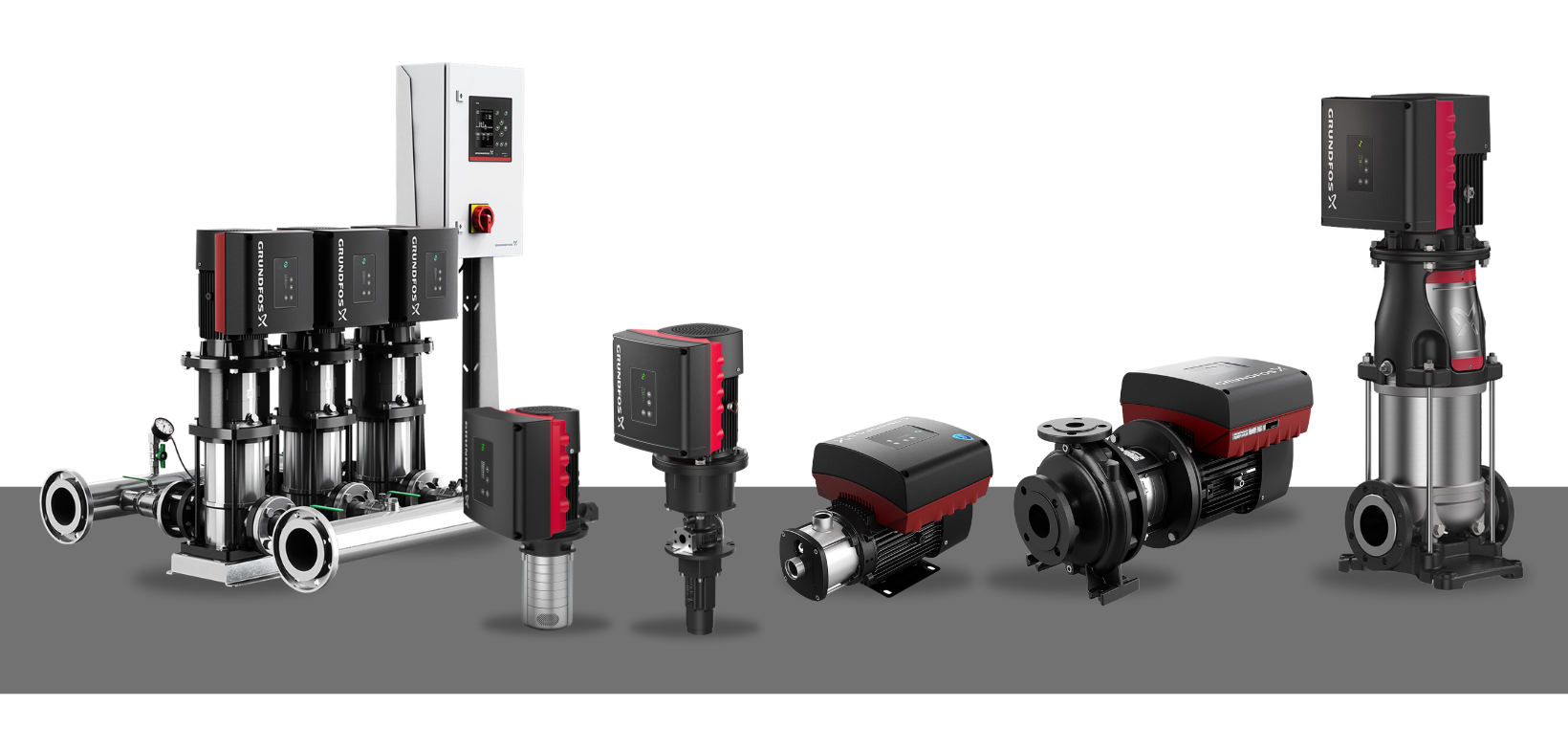

Making a difference with “E”

The “E” is synonymous with energy savings and electronic control – and basically the bottom-line story of all Grundfos E-solutions. As a world market leader of intelligent, high-quality pumps and pump systems we feel an obligation to keep at the forefront of the technological development, introducing truly innovative solutions for the benefit of our customers and the environment. This is exactly what we do with our comprehensive E-pump programme. Radiating quality and innovation inside out, Grundfos E-pumps with integrated frequency converter are designed with total control, customer convenience, and environmental sustainability in mind.

The need for speed control

The ability to control pump speed according to current demand is the single most important factor in reducing a pump’s life cycle costs and energy consumption, because around 85% of the total cost of owning a pump during its life is attributed to power consumption. With a Grundfos E-pump, energy consumption can be reduced drastically – in some applications with up to 50%. So it is not too much to claim that a Grundfos E-pump is the obvious choice. Along with speed-control functionality and built-in controller, Grundfos E-pumps are packed with intelligent features that make installation, operation, and service exceptionally easy and much less time consuming than a speed-controlled pump solution with conventional frequency converter.

When only the best is good enough

Grundfos has several decades of experience in building state-of-the-art E-pumps with energy-saving and speed-control functionality for domestic, commercial, and industrial pump applications. In fact, the world’s first speed-controlled pump with integrated frequency converter saw the light of day in our laboratories back in the late 1980s, and, ever since, we have worked intensively to optimise and extend the E-pump programme every year.

The entire E-pump programme is based on innovative pump technology and the Grundfos MGE motors (Motor Grundfos Electronic), which are high-efficiency motors with a built-in frequency converter and controller with pump-related functions. All Grundfos E-pumps comply with EMC and other international standards. They are manufactured exclusively in-house to guarantee outstanding quality and performance, and not least a meticulous attention to every detail. So when you buy a Grundfos E-pump, you buy quality from top to bottom!

Versatile application

E-pumps are ideal anywhere you need an integrated pump solution, in variable-load operations, and in applications where a high degree of process control is of the essence. They are typically used in the following industrial and commercial building applications:

- Heating and air-conditioning systems

- Pressure boosting systems

- Industrial cooling systems

- Process systems with fluctuating load

- Irrigation systems

ENERGY SAVINGS AND OTHER GREAT BENEFITS

E-pumps with built-in frequency converter are developed with optimum electronic control in mind. They provide several added benefits compared to a conventional solution with a separate standard frequency converter.

A perfect match

Pump, motor, and frequency converter are perfectly configured and interfaced, ensuring optimum reliable operation at all times. Furthermore, functionalities are matched to the specific pump application.

Total security

Because the entire E-pump solution is supplied by Grundfos, we take complete responsibility for all interfaces and the reliable interaction of all components; not only pump, motor, and frequency converter but also the sensor and the application software. This greatly facilitates the initial buying situation as well as any subsequent aftersales service.

Ease and simplicity

An E-pump is just as easy to install as a standard pump. With Grundfos E-pumps it is simply “plug and pump” – no extra programming or cabling is needed. Once connected to the power supply, the E-pump is operational.

Driving down life cycle costs

Employing variable-speed pumps with an integrated frequency converter will markedly cut planning, purchasing, installation, and commissioning costs. Also the operating costs are significantly reduced due to the E-pumps’ special pump functionalities and automatic energy optimisation.

Reduced noise level

Due to the high switch frequency from the frequency converter to the motor, an E-pump will operate very silently compared to many standard frequency converters.

Extended flexibility

E-pumps are ideal when pumps need replacing, as they do not require extra space or wiring in the control cabinet. The innovative design and modular concept provide maximum flexibility in new as well as in redesigned plants.

Save money as you save energy

Regulating pump speed according to demand is positively the best way to reduce energy consumption and operating costs. The Flux Control functionality in the MGE motor offers integrated automatic energy optimisation. In practise this means that the frequency converter minimises motor losses at all times, depending on the actual motor load.

Grundfos E-Pumps

Cool and convincing. Smart features.

E-pumps offer a superb array of pump-related functions that your system will benefit from with respect to operating economy, comfort, user friendliness, and process adaptability.

Smart user interface

All E-pumps are equipped with an operating panel from where basic functions like start/stop, setpoint setting, reading operating conditions, etc. can be carried out.

The universal Grundfos R100 IR remote control unit can be used in connection with installation, commissioning, operation, service, and fault finding of a number of Grundfos products – including also the E-pumps. R100 furthermore provides access to several extended functions and unique possibilities for reading operating conditions such as power consumption, actual value of pressure, alarms, and so on. The R100 unit has an intuitive, easy-to-use menu structure, making commissioning and operation of the E-pumps very user-friendly

Proportional pressure

The proportional pressure function ensures that the differential pressure in a circulating application, e.g. a heating or an air-conditioning system, is sufficient at low-flow as well as at high-flow demands. The differential pressure is automatically raised with increased flow.

Dry-running protection

E-pumps can be protected against dry running, as one of the inputs can be dedicated to a dry-running detector

Duty/standby

By interconnecting two CRE pumps via the standard built-in GENIbus interface, a duty/standby function of the two pumps can be obtained (not available in all E-pump types).

Constant – whatever you want!

When we say constant, we mean constant! E-pumps have a built-in PI controller that provides closed-loop control of virtually any value you want to control (available functions depend on E-pump type and variant). For example:

- Constant pressure with or without stop function

With stop function: The head is kept constant at high flow. On/off operation at low flow.

Without stop function: The pressure is kept constant irrespective of the flow.

- Constant differential pressure.

The differential pressure is kept constant irrespective of the flow.

- Proportional pressure

The head is reduced at low flow and increased at high flow.

- Constant level

The fluid level is kept constant irrespective of the flow.

- Constant temperature

The fluid temperature is kept constant irrespective of the flow.

Stop function

In most water supply applications the required flow can be very low, sometimes even equal to zero. In those situations on/off operation of the pump according to demand is more economical. The CRE pumps for water supply applications offer this stop function in constant pressure applications. The stop function furthermore prevents the pump from running against closed valve with the risk of heating up the water in the pump, and thus growth of unhealthy bacteria or damage of the shaft seal.

Advanced functionality for large E-pumps

MGE motors from 11-22 kW offer even more advanced functions, further increasing the benefits of using E-pumps.

- Motor bearings supervision

The large E-pumps (11-22 kW) are delivered with a motor bearings monitoring function that displays an automatic warning when it is time for relubrication or replacement of bearings. This function can be further optimised by the addition of bearings temperature measurement (requires an IO module), which provides a warning or discontinues pump operations automatically in case of overheating. - Stand still heating

An anti-condensation heater function makes it possible to heat up the motor during stand still to avoid condensation in the motor